A nice dummy load

I've been building audio amplifiers for years. And until now I've always used just a bare wirewound resistor with some banana plugs as a test load. Well, no longer! I now have a very nice dummy load:

It's a simple thing, really, but I thought others might get some inspiration and/or at least be interested in the sources for the bits and pieces I used.

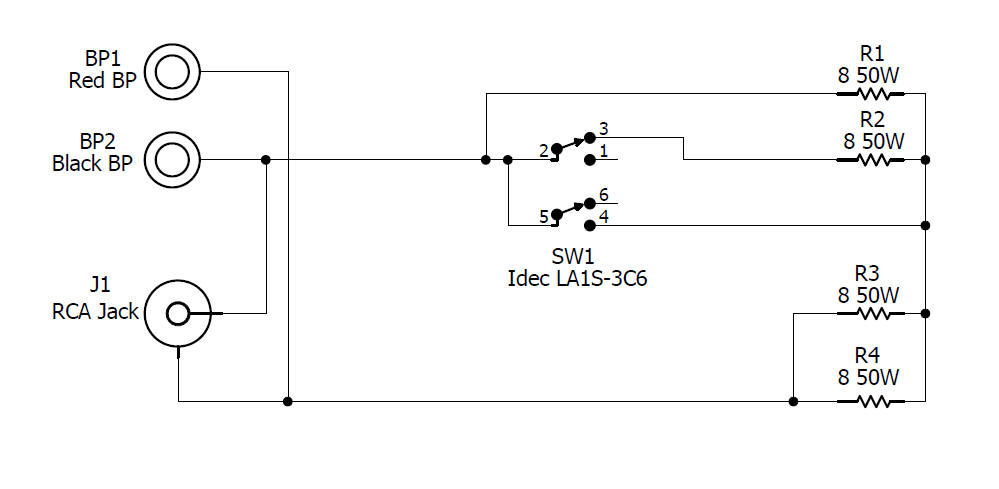

The binding posts are used to connect to the amplifier. I added RCA jacks in parallel, to allow a monitor connection to the audio analyzer (or other test & measurement apparatus).

I used some nice big 8 ohm 50W (or 100W when heatsinked) power resistors that I found cheap at Surplus Sales of Nebraska (www.surplussales.com). The specific item is the (RWF) 12M59-8-L on this page: http://www.surplussales.com/Resistors/NonInductive/Res-NonInd_list.htm It's priced well - I bought 10 pcs. for $45.00. These are nice metal-tubbed power resistors made by Milwaukie resistor.

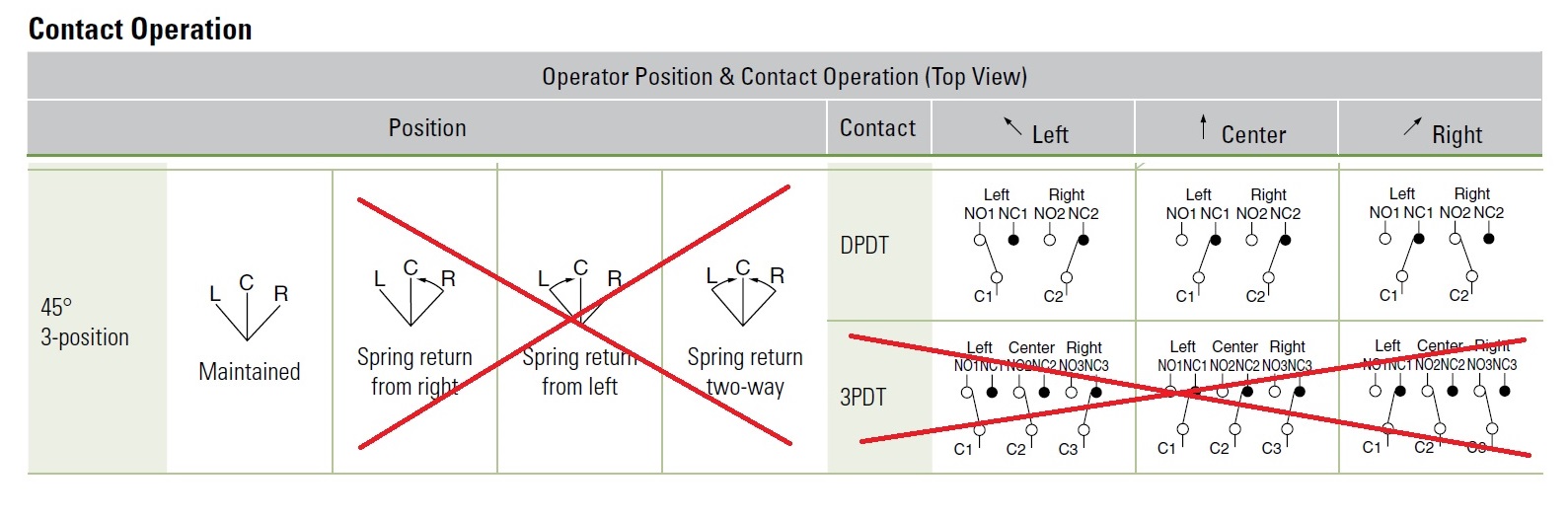

I used a "selector switch" from Idec to allow selection of 4 ohms (two resistors in parallel), 8 ohms (4 resistors in series-parallel), or 12 ohms (one in series with two in parallel). Really, the only reason for the 12 ohm load is that I use this to measure Zout of an amplifier, by measuring the output voltage difference form 8 to 12 ohms. The switch is a little odd... it is a DPDT switch but has three positions. In the center position, one pole is open, and the other closed. It's a little hard to understand how all this works, but I'll leave that to you to figure out :)

You can buy this switch direct from Idec or from distis like Allied Electronics. They aren't cheap, at around $25 each, but they are nice. By the way, I think this particular switch series (called L6) is being discontinued, but there is another model (LB1S-3T6).

The enclosure is a chassis from Landfall Systems. This chassis works really well to use with an extruded heatsink. The chassis top plate is the extrusion. Landfall can make one of these for you, or something different in a similar size.

The extrusion came from Heatsink USA. They are one of the only vendors I know that will supply smaller cuts of heatsink extrusion for a reasonable price. This particular heatsink is the 7.28" wide extrusion. I ordered it cut to 10" long (which they do an excellent job of, by the way - a very clean cut with no need to do any cleanup). This extrusion works particularly well with the Landfall chassis, as the outer fins line up correctly with the mounting holes in the chassis.

I drilled counterbored holes through the top of the extrusion to mount it to the chassis, and drilled blind holes in the back and tapped them #8-32 to mount the power resistors. Use plenty of grease with these resistors as they are not exactly flat on the back. This is pretty easy to do if you have a drill press. Landfall might be willing to do this for you for a small fee...

Landfall also had the extrusion and chassis black anodized for me, then engraved the front with the legends you see in the photo above.

It came out beautifully. It should be able to handle 400W per channel on the 8 ohm setting, with less (200W @ 4 ohms and 125W @ 12 ohms) for some period of time. Of course it will get hot - the heatsink theta-JA is about 0.4 degrees C per watt, so it will be at about 100C with 100W/channel continuous (it would probably take an hour to heat up that much due to it's thermal mass). Far more than I'll probably ever need.